Overview

Ensuring Turbine Stability: Advanced Turbine Bypass Solutions

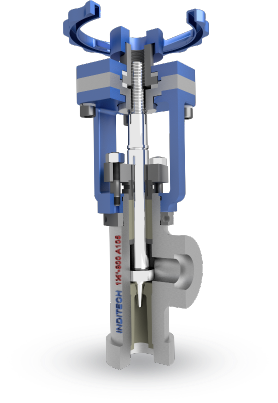

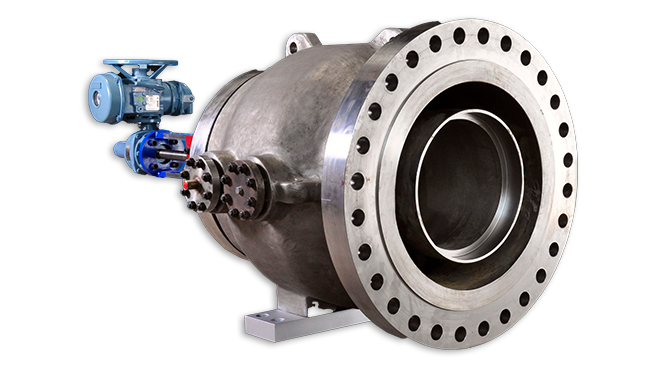

Angle Type Turbine Bypass Valve

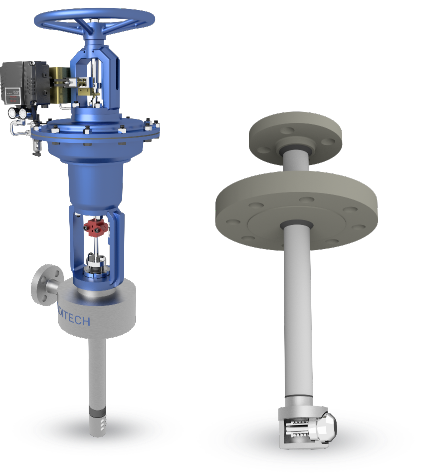

Steam Turbine Bypass is a severe-service Steam Conditioning application due to critical requirements of fast opening, perfect sealing and frequent start-up from cold or warm conditions. Turbine Bypass Valves provide system protection to upstream and downstream plant components and sometimes perform these tasks in a fraction of a second.

Turbine Bypass Valves are subjected to large thermal stresses due to the rapid and sudden opening of the valve during a turbine trip sequence.

These valves are generally manufactured from forged materials, allowing for higher strength and durability compared to equivalent cast materials.

Optimize your turbine's efficiency and extend lifespan with our precision-engineered bypass valves.

Technical Data

300/270

Angle Type/Globe Type

Inlet – NPS 1 (DN25) to NPS 24 (DN600)

Outlet – NPS 2 (DN50) to NPS 48 (DN1200)

CL150 to CL2500

Socket Weld/Butt Weld/Flanged

Angle Type – A105; A182 F11/F22/F91

Globe Type – A216 WCB; A217 WC6 /WC9/C12A

Linear/Modified Linear/Equal %/Modified Equal %

Class IV/Class V

Pneumatic/Motorised/Electro-Hydraulic

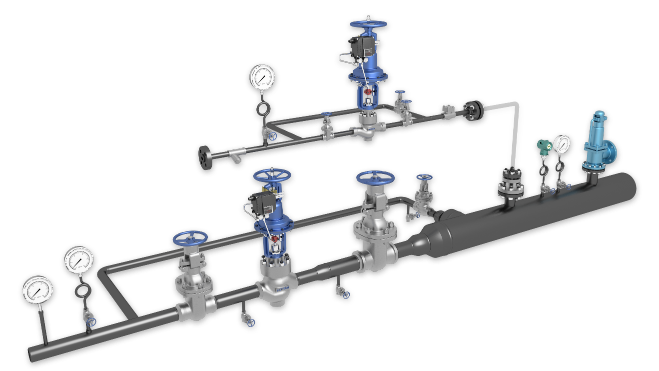

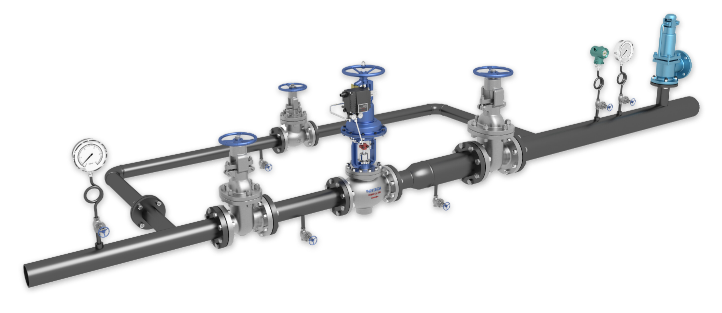

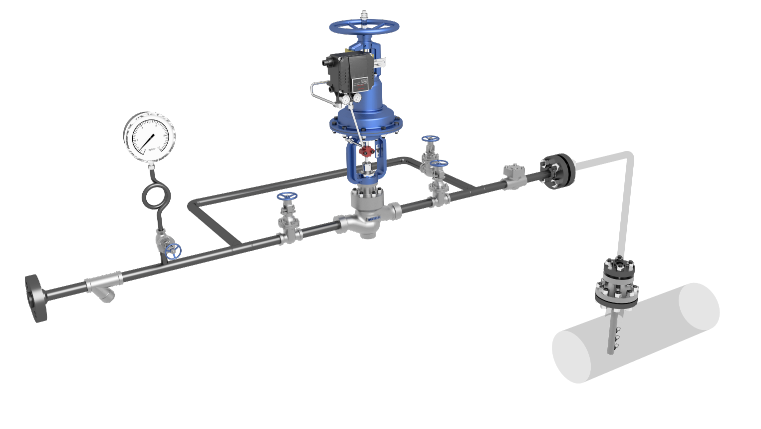

- Spray Water Control Valve

- Dump Tube (can be supplied on request)

- Steam blow-out kit (can be supplied on request)

Features

- Rangeability of 40:1 for both steam & water that provides good control from low load to high load

- Pressure Seal Bonnet for #1500 & #2500 that maintains pressure boundary integrity of the body-bonnet joint

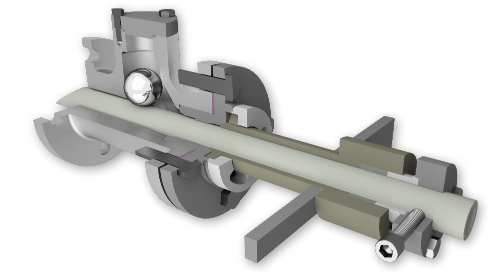

- Pilot-operated balanced plug that ensures perfect sealing

- Low Noise generated due to specialised trim with micro-drilled holes & 1 or 2 additional diffusers

- Desuperheating through steam-assisted nozzles or spring-loaded nozzles is available

- The spray nozzles' size, quantity, and placement for each application are meticulously optimised to ensure optimal distribution and coverage throughout the flow stream.