Overview

Flow with Confidence: Reliable and Efficient Control Valves for Every Flow Challenge

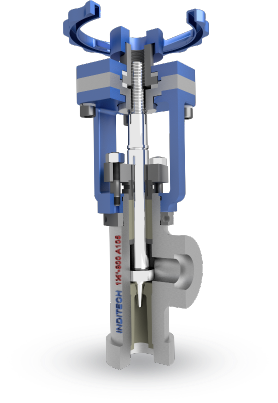

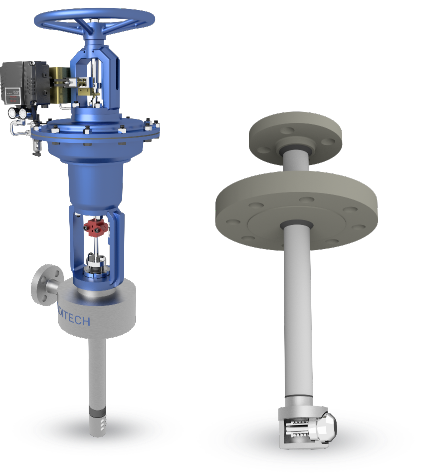

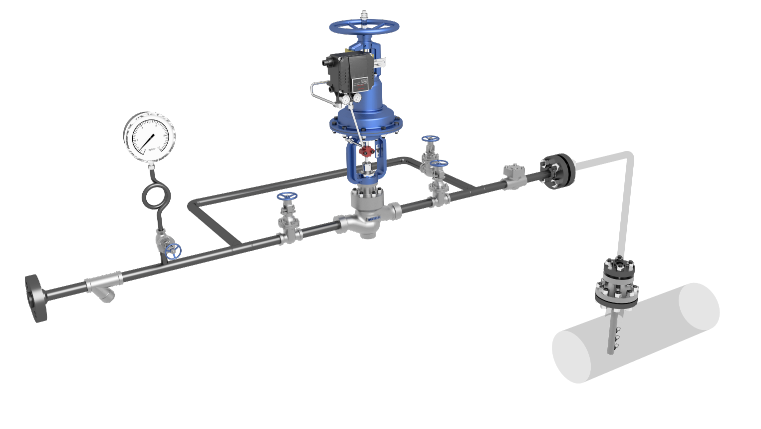

Motorised Control Valve

Flow control is the heart of any industry, and control valves play a pivotal role in maintaining the desired parameters of a process. At their core, control valves manage the rate of fluid flow by adjusting the size of the internal flow passage. Control valves utilise an actuator, triggered by a signal, to modulate the flow path and precisely regulate the fluid stream.

Control Valves help to:

- Regulate Flow: Flow control valves ensure that every process receives the precise amount of flow it needs.

- Manage Pressure: Pressure Control Valves ensure that all downstream equipment operates at the right pressures and keep the pressure in check, safeguarding equipment and personnel.

- Govern Temperature: Precise flow regulation translates to controlled temperature fluctuations. Temperature Control Valves prevent overheating in a manufacturing process or maintain the delicate balance in a chemical reactor.

- Maintain Level: From ensuring consistent liquid levels in storage tanks to regulating the water level in a boiler, Level Control Valves keep liquids and gases flowing at the right depth.

At IndiTech, we’re more than just a valve manufacturer; we’re your trusted partner in flow control. We offer a diverse portfolio of solutions, each tailor-made to meet the unique needs of your industry. From expert valve selection and installation to ongoing maintenance and technical support, we’re with you every step of the way.

Maximize process efficiency with our high-performance control valves.

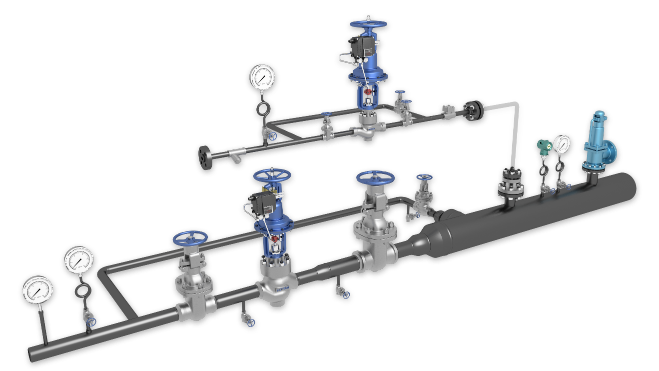

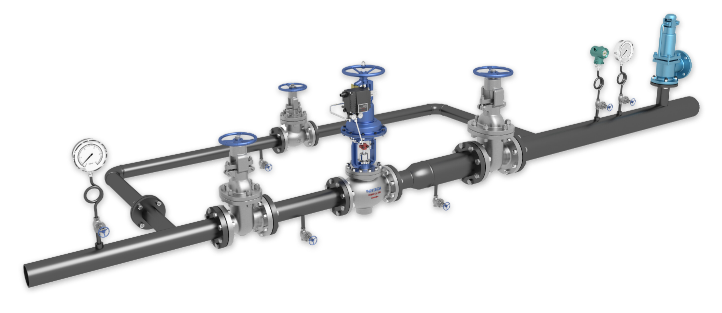

Applications

100% & 30% Feed Water Control Valve:

Feed control valves are essential for ensuring a steady and reliable supply of feedwater to the boiler. The 100% feed control valve is used during high-load periods, whereas the 30% valve is used at partial-loads offering finer control over the feed water flow.

Start-up Vent Valve:

The Start-up Vent Valve in boilers is a severe service application that helps in venting the steam from the system during the plant start-up phase.

Attemperator Control Valve:

The Attemperator Control Valve manufacture in boilers plays a critical role in regulating the temperature of the final superheated steam by injecting water into it.

Auto Gland Seal Control Valve:

An Auto Gland Seal Control Valve automatically regulates the pressure of sealing steam around a turbine shaft, preventing air leaks and minimising steam loss. It essentially maintains a balanced “barrier” preventing external air from entering the turbine while allowing controlled leakage of sealing steam outwards.

Condensate Pump Recirculation Valve:

Condensate Pump Recirculation Valve Maintains optimal flow and prevents cavitation by recirculating excess condensate back to the suction of the condensate pump.

Exhaust Casing Drain Valve:

The Exhaust Casing Drain Valve drains away condensate from the turbine & maintains pressure balance.

Boiler Feed Pump Recirculation Valve:

The boiler feed pump recirculation valve regulates the bypass flow from the pump outlet back to the deaerator. This bypass flow prevents overheating and cavitation of the pump.

Deaerator Level & Pressure Control Valve:

The Deaerator Level & Pressure Control Valve maintains optimal water levels and pressure within the deaerator, ensuring efficient removal of dissolved gases such as oxygen from the boiler system.

Soot Blower Control Valve:

A soot blower control valve regulates the release of steam to remove accumulated soot and ash from the interior walls of the boiler heating surfaces.

Hotwell Level Control Valve:

The Hotwell Level Control Valve in a steam turbine system helps to manage the water level in the condensate hotwell. This tank collects condensed steam from the turbine exhaust, and maintaining its level is crucial for efficient and safe operation.

Exhaust Hood Spray Valve:

The Exhaust Hood Spray Valve sprays water into the turbine exhaust hood, thereby preventing overheating & optimising performance.

Vacuum Breaker Valve:

The Vacuum Breaker Valve acts as a safety valve for the turbine’s vacuum, letting in air to prevent implosion due to sudden loss of vacuum in the condenser & for quick shutdown during emergencies.

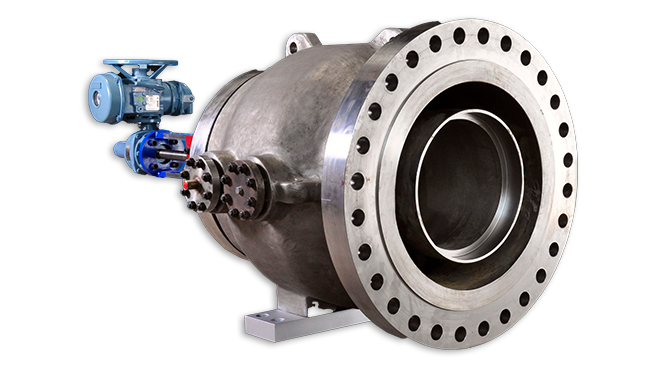

Technical Data

INDITECH SERIES

210

VALVE SIZE

NPS 0.5 to NPS 24 (DN15 to DN600)

PRESSURE RATING

CL150 to CL2500

DESIGN STANDARD

ASME B16.34; ISA 75.01.01

END CONNECTIONS

Flanged/Socket Weld/Butt Weld

BODY MATERIAL

A216 WCB; A217 WC6/WC9/C12A; A351 CF8/CF8M

CHARACTERISTICS

Linear/Modified Linear/Equal %/

Modified Equal %/On-Off

LEAKAGE CLASS (FCI 70.2)

Class IV/Class V/Class VI

OPERATION

Pneumatic/Motorised/

Manual

ACCESSORIES

- Positioner (Pneumatic/Electro-pneumatic/ SMART)

- Air Filter Regulator

- Position Transmitter

- Air Lock Relay

- Limit Switch

- Solenoid Valve

- Volume Booster

Features & Benefits

- Streamlined body profile with excellent flow capacity and rangeability

- Wide range of trim options with customised flow characteristics in both balanced and unbalanced designs

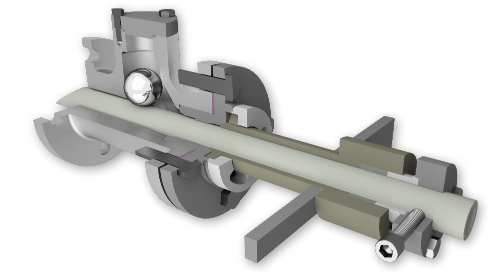

- Soft-seated/Hard-faced sealing surface options available

- Roller-burnished valve stem offers minimal friction

- Reliable leakage performance with sealing as per Class IV, Class V, Class VI available

- High-performance PTFE/Graphite stem sealing

- Various bonnet types, from Standard Bolted, Cooling Fin to Pressure Seal Bonnet available