Overview

Safeguard your lance replacement operation with our Ball Check Valves.

Application Criticality

Common challenges encountered during injection lance replacement:

- Possibility of serious accidents due to leakage of hot blast gases at ~1200°C

- Unsafe operation due to jamming/failure of internal components of NRV

- Loss of productivity due to the requirement of BF shutdown/downtime for injection lance replacement

- Difficulty in fast turnaround due to heavy & cumbersome equipment

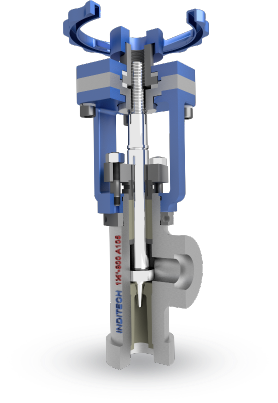

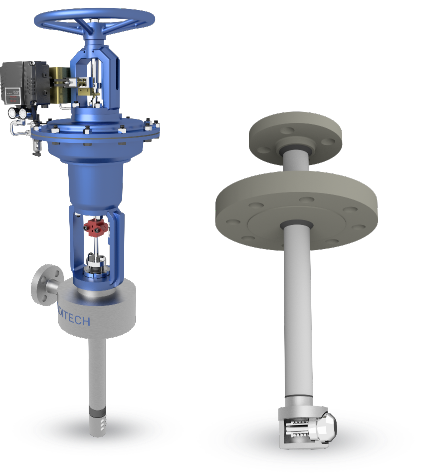

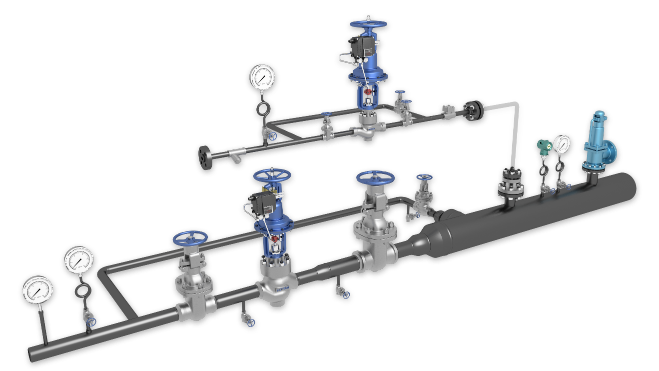

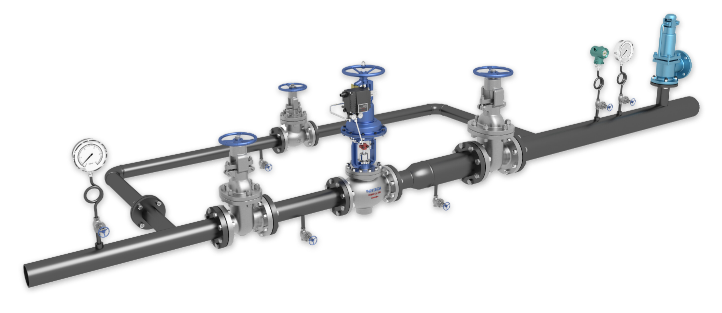

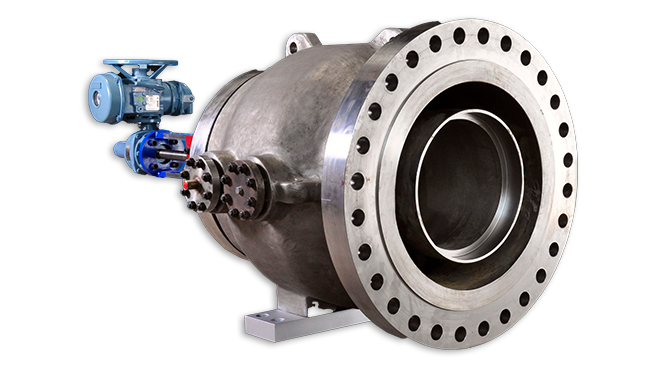

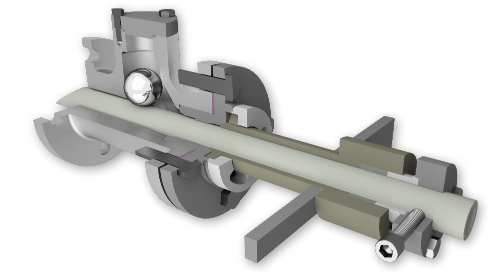

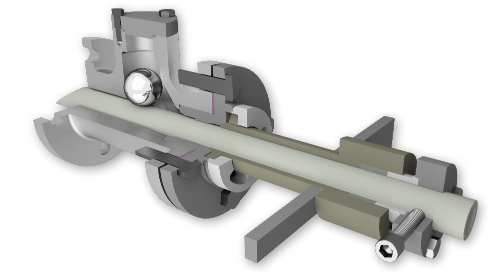

IndiTech offers a special lifting ball type check valve (also known as bullet valve) to solve the challenges mentioned above. Its simple design, tight sealing and high performance make it ideal for this critical application.

Customer References

Client Testimonials

The NRVs supplied by IndiTech Valves have facilitated online insertion and removal of the Injection Lance, without the need for Blast Furnace shutdown, thereby significantly reducing downtime of the Blast Furnace.

Mr. R. Khamkar

General Manager, SLR Metaliks

Overall performance of the BF Check valve supplied by IndiTech Valves Pvt. Ltd., Pune is good. Workmen are happy with the design due to ease in removal & fitment of the pulverized coal injection lance.

Mr. Roshan V Naik

Manager, Vedanta Sesa Goa

We have visited the works of IndiTech Valves for the kick-off meeting of SAIL Rourkela BF-1 Injection Lance Assembly. The setup is good with a lot of potential for future growth. People are with sound technical background and very cooperative.

Mr. Shailendra Sharma

Manager – Inspection & Expedition, Danieli Corus IndiaTechnical Data

330

DN40 (suitable for lance OD ½”)

DN50 (suitable for lance OD ½”, ¾”, 1”)

CL150/CL300/PN40

Flanged

A216 WCB

SS 316

ASME B16.34

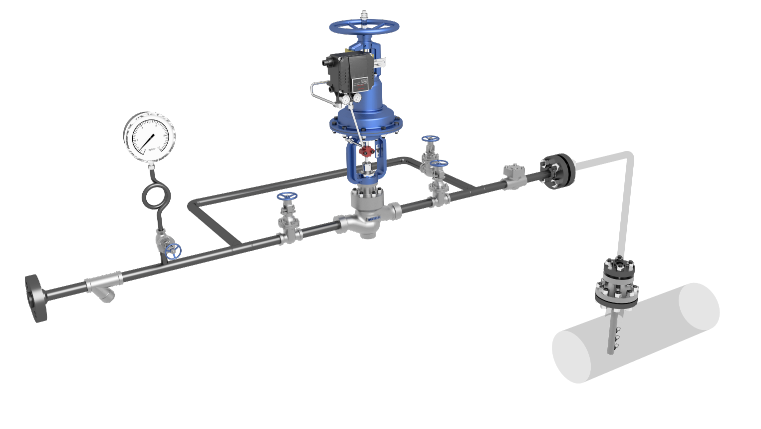

- Ball Check Valve (NRV) only

- Complete Injection Lance Assembly

- Injection Lance only

Features

- Proven solution that is 100% safe for operators

- Precise manufacturing that ensures immediate closure of NRV as soon as Injection Lance is removed

- Precision machined sealing surfaces for consistent leak-proof performance

- Facilitates online replacement of Injection Lance without need for BF shutdown

- Simple yet effective design, which makes it very easy to use & operate

- Successful track record since 2005

IndiTech Advantage

We can provide completely customised solutions to suit your existing space & design constraints