Overview

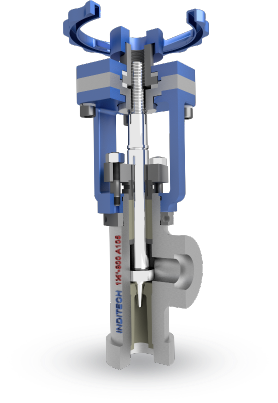

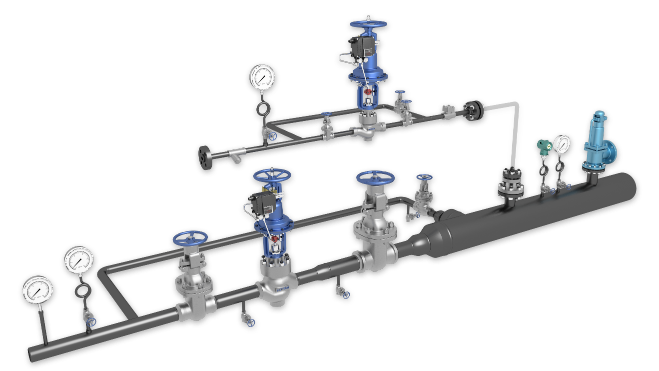

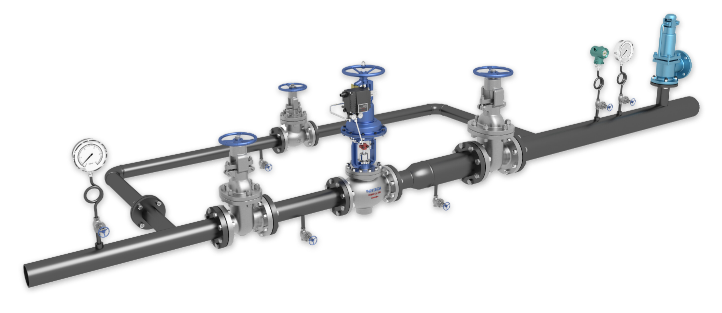

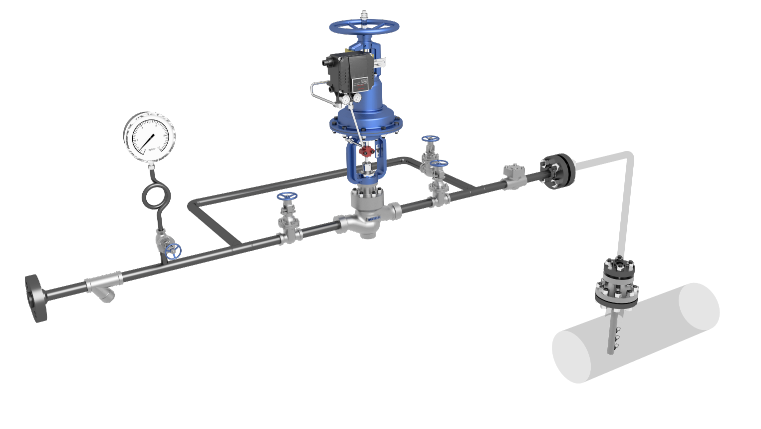

3-Way Valves feature three ports: either one inlet and two outlets or one outlet and two inlets. This unique configuration enables them to perform a variety of functions. 3-Way Control Valves provide dynamic control options. Users can divert, mix or isolate flows based on specific operational requirements. A 3-Way diverting valve splits a common fluid stream into two outlet ports. A 3-Way mixing valve combines two fluid streams and discharges the mixed fluid to a common outlet port.

Get versatility and control with our energy-efficient 3-Way Globe Valves.

Applications

Steam Power Generation:

3-Way globe valves are used to regulate the feed water flow to the boiler drum by diverting the excess flow back to the boiler feed pump through the recirculation line.

Temperature Control Systems:

3-Way globe valves are used to modulate hot and cold fluid flow in applications such as thermic fluid systems, dryers, HVAC systems, and heat exchangers. Thus playing a key role in accurate temperature control.

Process Industries:

3-Way globe valves are crucial in return condensate lines for CCDS (Condensate Contamination Detection) systems across various process industries.

Food & Beverages:

3-Way globe valves are also used to mix or blend different ingredients in meticulously designed food and beverage formulations.

Technical Data

220

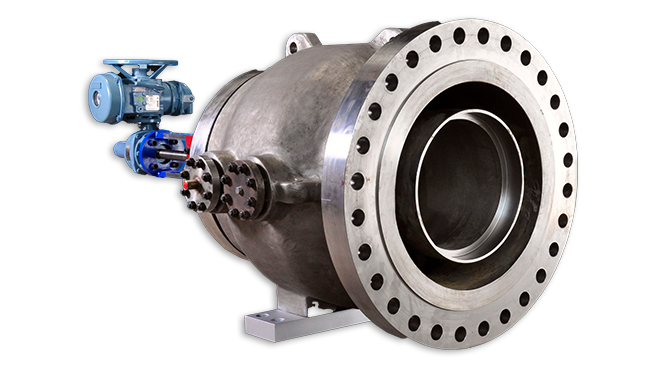

NPS 1 To NPS 24 (DN25 To DN600)

ANSI CL150 To CL2500

ASME B16.34; ISA 75.01.01

A216 WCB; A217 WC6/WC9; A351 CF8M

Flanged/Socket Weld/Butt Weld

Class IV/Class V

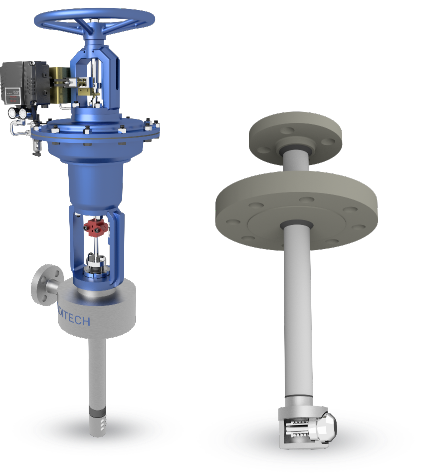

Pneumatic/Motorised/Manual

Control/On-Off

Diverting/Mixing

Features

- Streamlined valve body design optimised to handle high-capacity flows

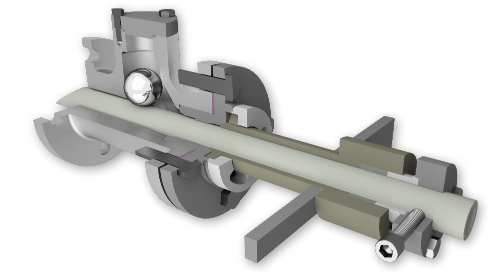

- Slotted plug with inherent linear flow characteristics for Regulating Control Duty

- Disk type plug for On-Off Duty

- Vibration elimination through trim provided with both top guiding & seat guiding

- Easy in-line maintenance facilitated by both top and bottom entry access to valve internals

- Modular design with interchangeable parts for both mixing and dividing designs