Overview

Achieve Precise Steam Temperature Control with IndiTech’s Range of Desuperheaters

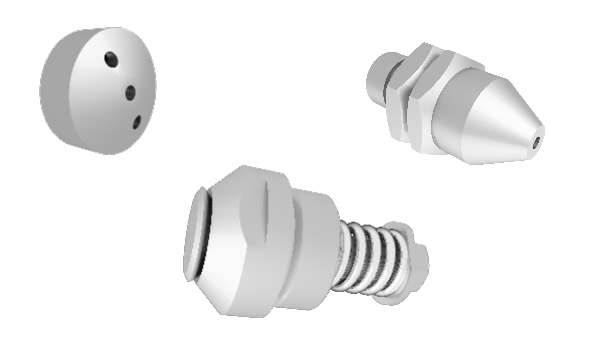

Wide Range of DSH Nozzles

Desuperheaters are essential components in many industrial processes. They are used to reduce the temperature of steam to a desired level. This is important for several reasons, including:

- To prevent damage to downstream equipment: Steam that is too hot can damage downstream process equipment, such as heat exchangers.

- To improve efficiency: Desuperheated steam has better heat-transfer efficiency since it is close to saturation temperature.

- To ensure good final product quality: The temperature of steam plays a critical role in determining the final quality of products such as sugar, paper, textiles, etc

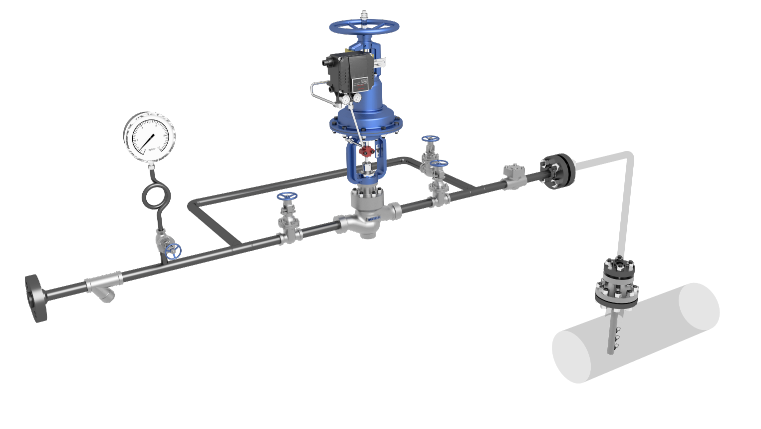

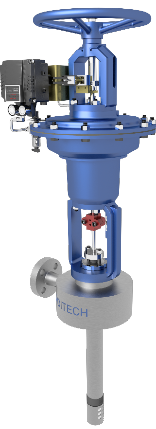

A Desuperheater injects atomised water into the steam flow and thus reduces the temperature to the desired set point. IndiTech has a variety of Desuperheater designs to suit multiple service applications. IndiTech also caters to the stringent demands of Attemperator applications, which are subjected to much higher pressure and temperature requirements than conventional process Desuperheaters.

Are fluctuating steam temperatures costing you downtime? Let our experts diagnose and take care of the issue.

Applications

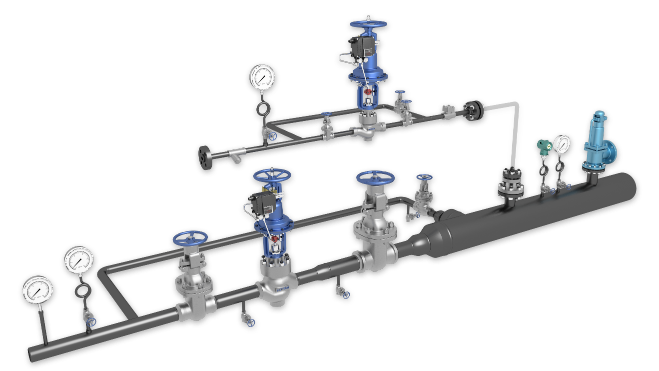

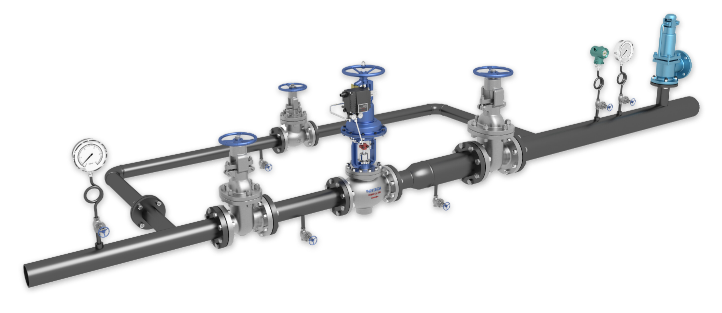

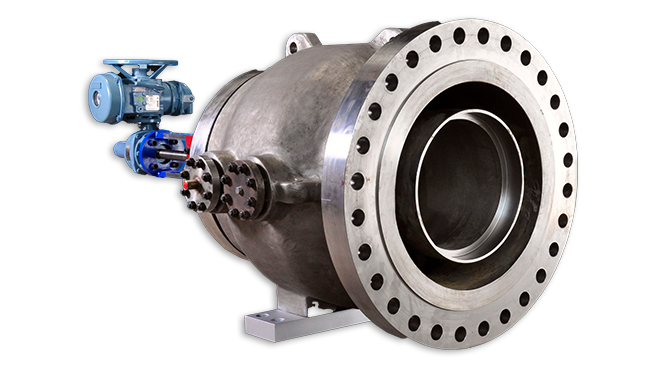

Attemperator between Primary (PSH)/ Intermediate (ISH)/Final Superheater (FSH):

Attemperators precisely control the steam temperature at various stages of superheating in industrial boilers. This is crucial for protecting turbine components from potential damage due to excessive heat and also to ensure optimal turbine efficiency.

Turbine Exhaust Desuperheater:

Turbine Exhaust Desuperheaters play a crucial role in regulating the temperature of steam after it exits the back pressure turbine. This desuperheater cools the exhaust steam from the turbine to an exact temperature, preventing damage and optimising performance.

Desuperheater for Auxiliary PRDS:

Auxiliary steam systems (like Ejector and Turbine Gland Sealing) often need steam at lower temperatures than superheated steam from boilers. Desuperheaters precisely control steam temperature by injecting water, ensuring it doesn’t exceed safe limits for downstream equipment.

Desuperheater for Deaerator Pegging PRDS:

Deaerator Pegging PRDS needs a Desuperheater to reduce the temperature of steam before it enters the deaerator, ensuring efficient oxygen removal. This optimises boiler performance and protects downstream equipment.

Desuperheater for Turbine Bypass PRDS:

The desuperheater in turbine bypass PRDS helps to control and reduce the temperature of steam in the bypass line, ensuring optimal conditions for turbine operation by removing excess heat.

Desuperheater for Extraction/Bleed PRDS:

The desuperheater in Extraction/Bleed PRDS regulates and lowers the temperature of steam extracted or bled from the turbine, optimising its utilisation in downstream processes.

Desuperheater for HP/LP Process PRDS:

The Desuperheater is used in multiple process PRDS applications (like Sugar mills, Chemical Plants, etc.) to control and reduce the temperature of steam, ensuring precise thermal conditions.

Technical Data

INDITECH SERIES

230/240/250/260

STEAM LINE SIZE

NPS 1 to NPS 80 (DN25 to DN2000)

PRESSURE RATING

CL150 to CL2500

BODY MATERIAL

A105; A106 Gr. B; A182 F11/F22; A335 P11/P22

NOZZLE MATERIAL

SS 316/SS 410 (Stellited Optional)

TYPE

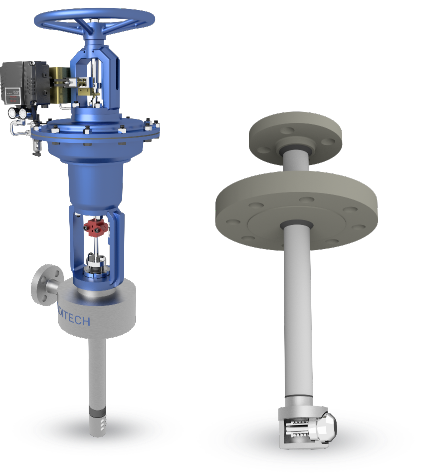

Separate Control Valve/ In-built Control Valve

TURNDOWN

Up to 40:1

Desuperheater Types & Features

Fixed Nozzle DSH

Fixed Nozzle DSH

Fixed Nozzle Desuperheaters are best suited for applications involving minimal load fluctuations.

- Suitable for turndown ratio up to 4:1

- Fixed area orifice Desuperheater

- Most simple and economical Desuperheater

- Spray nozzles have an in-built check valve to prevent the entry of steam into water line

- Capable of maintaining steam temperature to saturation + 6°C

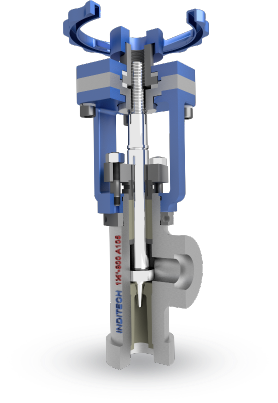

Spring Loaded Nozzle DSH

Spring Loaded Nozzle DSH

Spring Loaded Nozzle Desuperheaters are best suited for applications involving moderate load fluctuations.

- Suitable for turndown ratio up to 10:1

- Variable area orifice, back pressure activated Desuperheater

- Capable of handling high spray water flow rates

- Set pressure & spring range selection ensures sequential opening of the individual nozzles, thereby leading to precise control of water flow and, thereby temperature

- Capable of maintaining steam temperature to saturation + 6°C

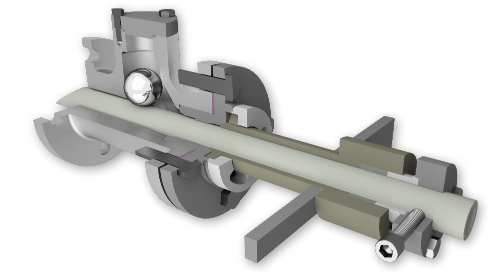

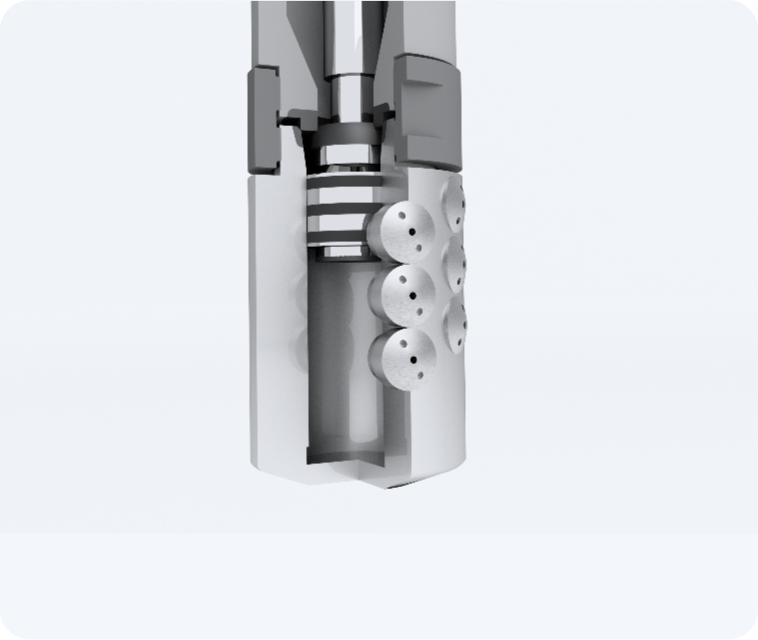

Variable Nozzle DSH

Variable Nozzle DSH

- Suitable for turndown ratio up to 40:1

- No external spray water control valve is required

- Wide range of Kv / Cv values is possible by using special nozzle combinations

- Spray nozzles are vacuum-brazed to the body to prevent leakage

- Capable of maintaining steam temperature to saturation + 6°C

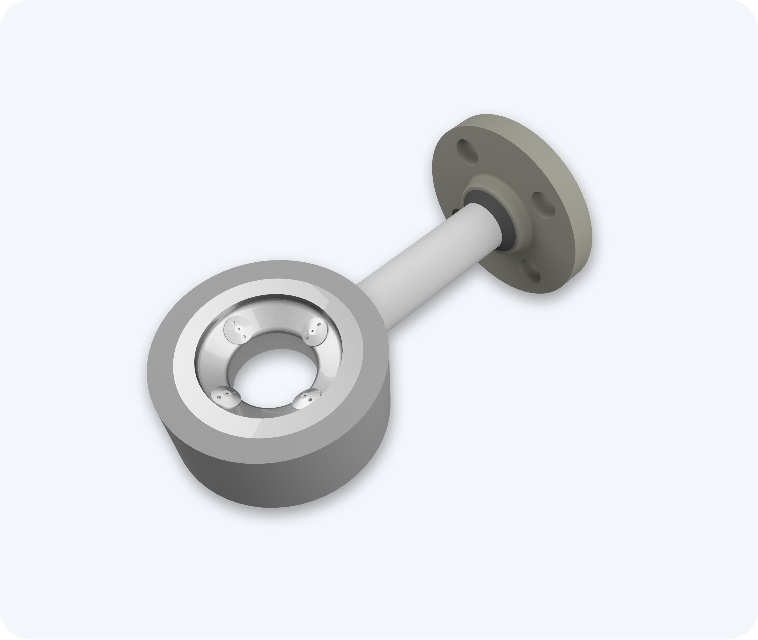

Venturi DSH

Venturi DSH

Venturi Desuperheaters are best suited for applications where water pressures are marginally above steam pressure.

- Suitable for turndown ratio up to 10:1

- Ideal for cases where water pressure is slightly more than steam pressure

- Efficient mixing due to water injection in highly turbulent & expanding steam after vena contracta

- Offers negligible steam pressure drop

- Capable of maintaining steam temperature to saturation + 6°C

IndiTech Advantage

The high-performance, custom-designed nozzles guarantee the water is atomised into a fine mist, regardless of the process conditions.