Overview

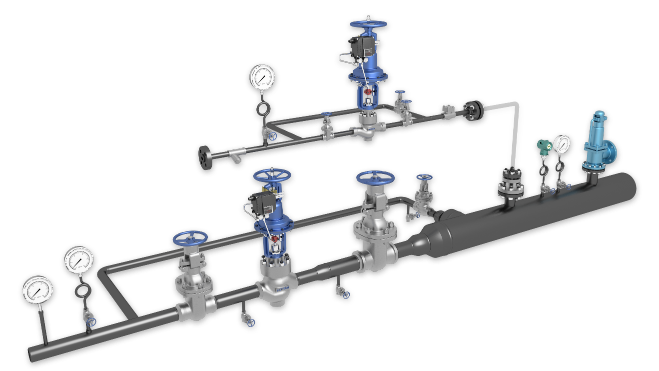

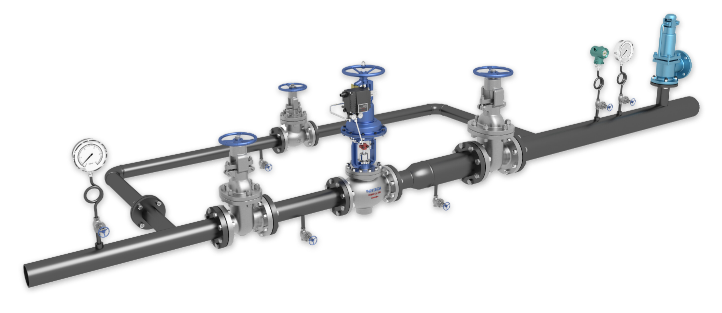

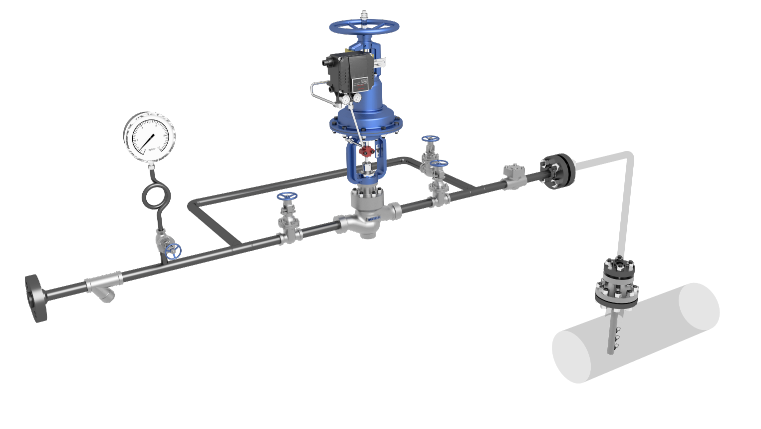

A pressure-reducing station (PRS), also known as letdown station, regulates the flow of high-pressure fluids to a desired, lower pressure This vital component ensures a continuous supply of fluids at optimum pressure and also safeguards the downstream equipment in countless industrial processes.

But the PRS system doesn’t just regulate pressure; it is indispensable in saving energy. By reducing pressure, the PRS System ensures that the process fluid is used only as needed, minimising waste and lowering operating costs.

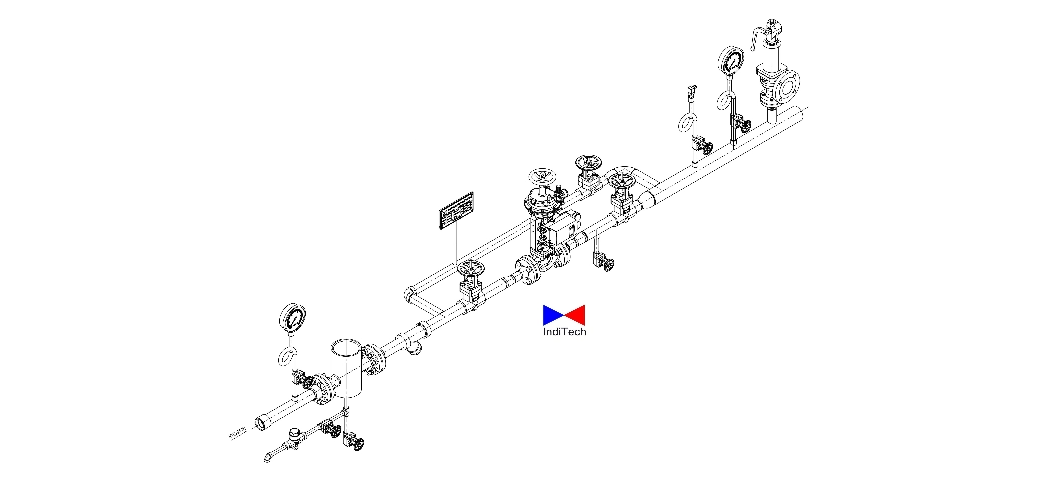

The IndiTech Pressure Reducing Station is a unified solution comprising carefully designed components working in perfect synchronisation. Each element collaborates to deliver a reliable and optimised performance, from precise pressure reduction to intuitive control systems.

Enjoy precise pressure control and worry-free operation with IndiTech’s advanced range of PRS Stations.

Applications

Steam Pressure Reducing Stations:

Several industrial processes require the reduction of boiler steam pressure to meet specific operational requirements, such as Food Processing, Textile, Chemical Processing, Pulp & Paper, etc.

Water Pressure Reducing Stations:

Reducing water pressure is often a key requirement in applications like cooling water systems to control the flow rate and pressure to achieve optimal heat exchange, spray drying in the food processing industry, etc.

Nitrogen Pressure Reducing Stations:

Lowering the pressure of Nitrogen gas is required in various industrial processes like Pharmaceutical, Food and Beverage Packaging, Steel Plants, Blanketing in Chemical Storage Tanks, etc.

Oxygen Pressure Reducing Stations:

Regulating the pressure of Oxygen is crucial in various process industries to ensure the safe and controlled use of Oxygen gas like Chemical Manufacturing, Medical Oxygen Supply, Water Treatment, Fuel Combustion Control, Steel and Metal Production, Chemical Oxidation Reactions, etc.

Other fluids on request:

Our PRS stations can be custom-designed for your specific process media requirements.

Technical Data

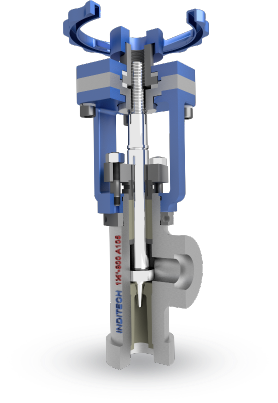

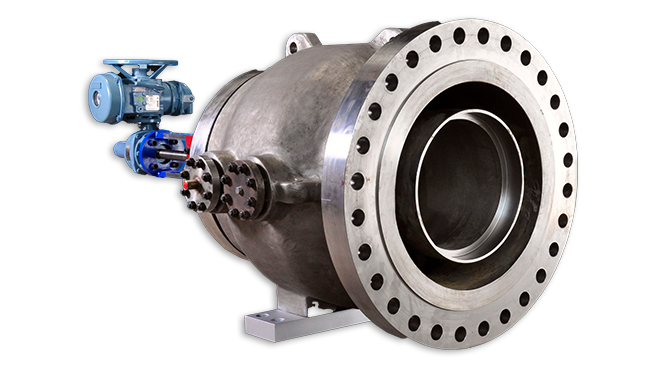

Inlet - NPS 1 to NPS 24 (DN25 to DN600)

Outlet - NPS 1 and above (DN25 and above)

CL150 to CL2500

A106 Gr. B; A335 P11/P22/P91

Flanged/Socket Weld/Butt Weld

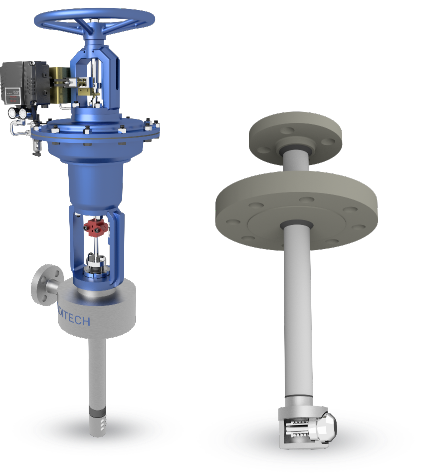

- Flow Meters

- Control Panels (PID controller-based/PLC-based)

- Strainers

- Steam Trap Module

- Moisture Separator

- Piping Supports

- Base Frame Skid

Features

- Modular Ready-to-Fit pressure-reducing solution

- Field-proven with over 250 installations worldwide

- Single-point contact vendor with complete package responsibility & guarantee

- Completely customised to suit customer pressure parameters

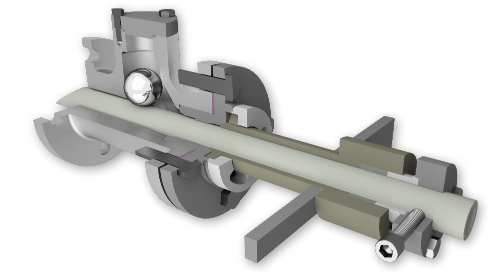

- Multistage pressure reduction based on process requirements to bring down noise level to accepted norms

- Full support for piping layout design can be provided on request

- Easy installation & maintenance