Overview

PRDS Station: Your One-Stop Solution for Precise Steam Conditioning

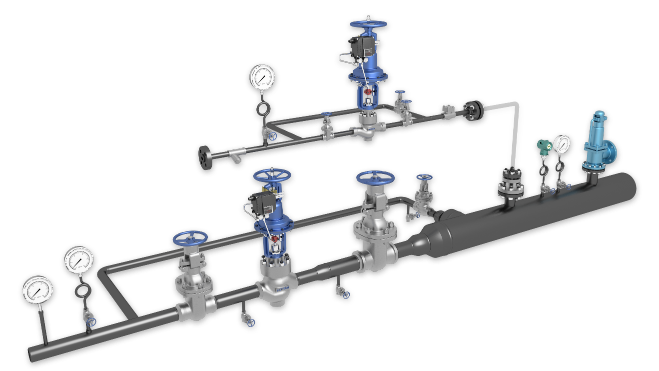

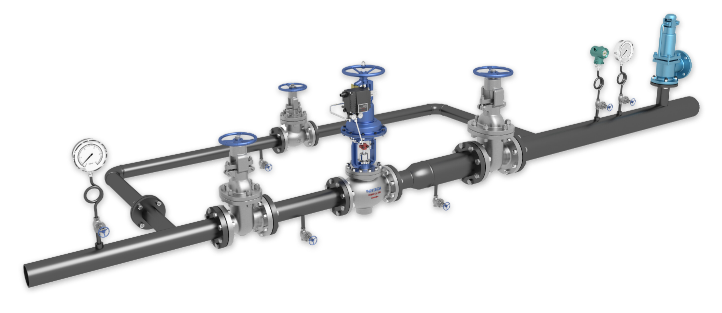

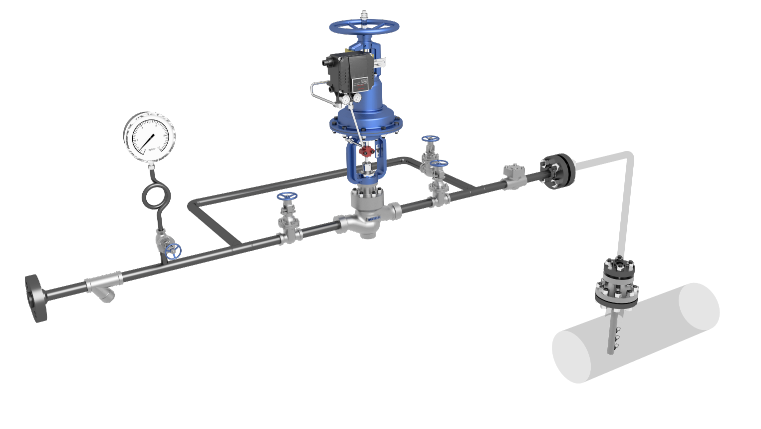

Combined PRDS Station

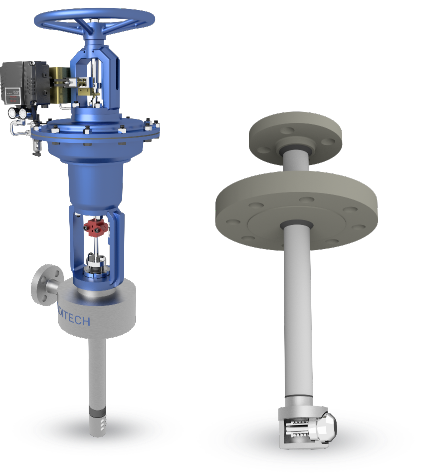

1. Pressure Reduction: A pressure control valve (PCV) regulates the steam pressure to the desired level, preventing damage to equipment and optimising efficiency.

2. Temperature Control: A desuperheater(DSH), working in conjunction with a temperature control valve (TCV), mixes atomised water with steam, effectively reducing its temperature to the required set point.

Enjoy precise pressure control, consistent steam quality, and worry-free operation with IndiTech’s advanced range of PRDS Stations.

Applications

HP/LP Process PRDS:

Multiple industries, like Sugar Mills, Paper Mills, Chemical Plants, Textiles, etc., utilise PRDS Stations to control and reduce the pressure and temperature of steam, ensuring precise thermal conditions for downstream processes.

Ejector & Gland Sealing/Auxiliary PRDS:

Ejectors are the devices used to create a vacuum in various processes, such as condensers or certain chemical processes. Gland sealing systems are crucial for preventing steam leakage and maintaining the integrity of the turbine casing. PRDS Systems helps maintain the desired steam pressure and temperature for optimal efficiency.

Deaerator Pegging PRDS:

Deaerator Pegging PRDS reduces the pressure and temperature of steam before it enters the deaerator, ensuring efficient oxygen removal. This optimises boiler performance and protects downstream equipment.

Turbine Bleed/Extraction PRDS:

The Bleed / Extraction PRDS station regulates and lowers the pressure and temperature of steam extracted or bled from the turbine, optimising its utilisation in downstream processes.

Turbine Bypass/Dump PRDS:

The Turbine Bypass PRDS System helps to control and reduce the pressure and temperature of steam in the turbine bypass line, ensuring optimal conditions for turbine operation by removing excess pressure and heat.

Technical Data

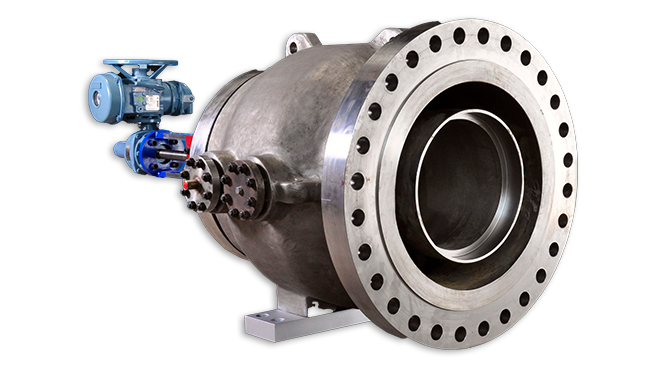

Inlet - NPS 1 to NPS 24 (DN25 to DN600)

Outlet - NPS 1 and above (DN25 and above)

CL150 to CL2500

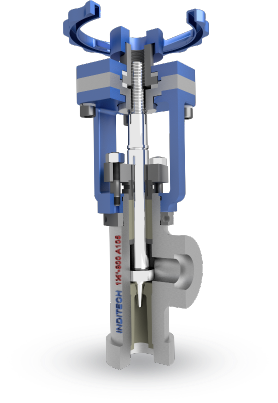

A106 Gr. B; A335 P11/P22/P91

Flanged/Socket Weld/Butt Weld

Separate CV & DSH/Combined PRDS

- Flow Meters

- Control Panels (PID controller-based/PLC-based)

- Strainers

- Thermal Liner

- Steam Trap Module

- Moisture Separator

- Piping Supports

- Base Frame Skid

Features

- Modular Ready-to-Fit steam conditioning solution

- Field-proven with over 500 installations worldwide

- Single-point contact vendor with complete package responsibility & guarantee

- Completely customised to suit customer pressure & temperature parameters

- Separate/combined systems based on technical feasibility

- Multistage pressure reduction based on process requirements to bring down noise level to accepted norms

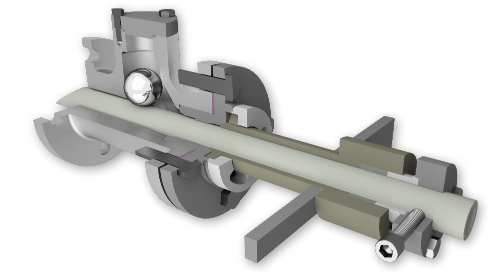

- Thermal Liner for pipe protection can be supplied for critical applications

- Various designs of desuperheaters to handle turndown ratios up to 40:1

- Temperature reduction up to saturation +6°C

- Full support for piping layout design can be provided on request

- Easy installation & maintenance